Non-toxic technology extracts more Gold from ore

Traditionally, once Gold ore is mined from the ground, it's crushed and leached. Cyanide is then used to separate the gold from the ore into the leached solution.

But traditional Gold production typically involves a famous toxin, cyanide, which has been banned for industrial use in several countries.

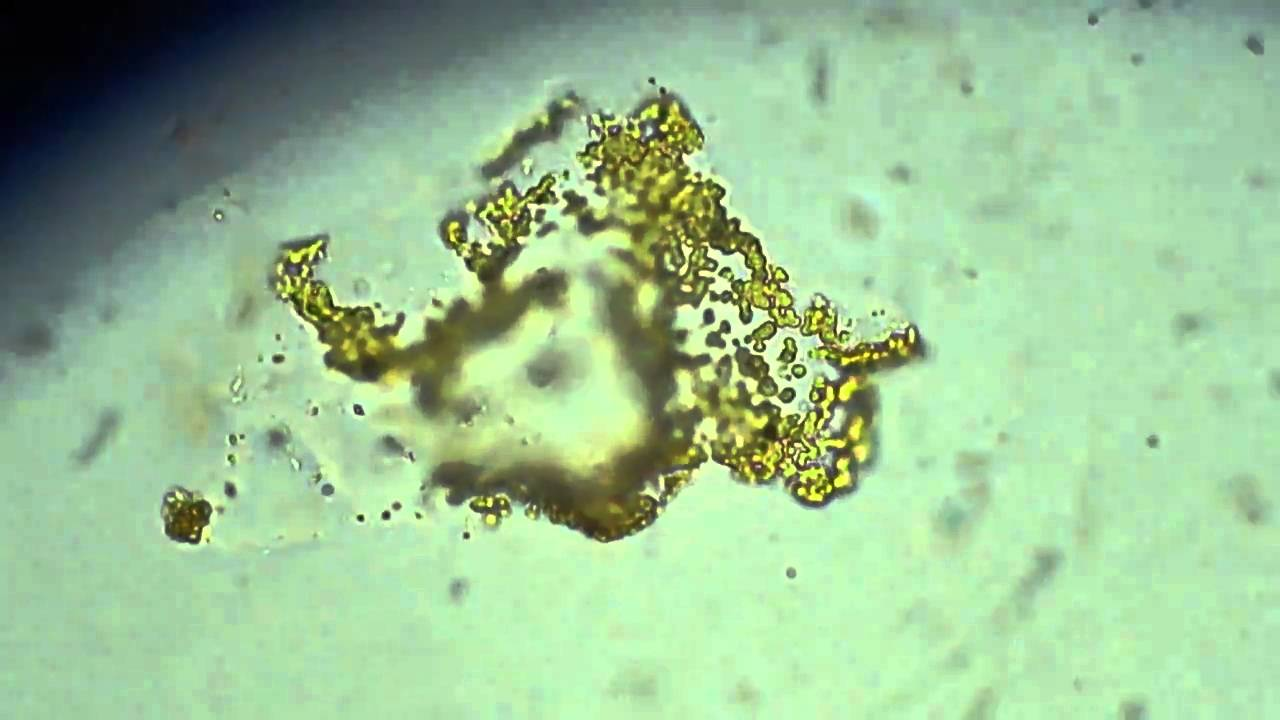

With the new process, the leaching and recovery process is done with Chloride.

The amount of gold been able to recover using Chloride is as high as 84%. In comparison, using the standard cyanide process with the same ore yielded only 64%.

The new process combines the best of two common methods for extracting leached Gold: electrolysis, which uses electric currents to reduce Gold or other metals present in the leaching solution, and cementation, which adds particles of other metals to the solution to react with the Gold.

The new process applies short pulses of electricity to create thin layers of metal—in our case Copper—on the electrode and cause a reaction that encourages Gold to replace the Copper layer.

Perhaps the new process cannot reach 100%, but it can hit the 90% mark or more.

English

English Arabic

Arabic