New method to extract and separate rare earth elements

Industrial waste from burning coal and mining other metals as well as electronic waste from cell phones and many other materials. These sources are vast but considered "low grade," because the rare earths are mixed with many other metals and the amount of rare earths present is too low for traditional processes to work well.

Furthermore, current methods for extraction and separation rely on harsh chemicals, are labour intensive, sometimes involve hundreds of steps, produce a high volume of waste, and are high cost.

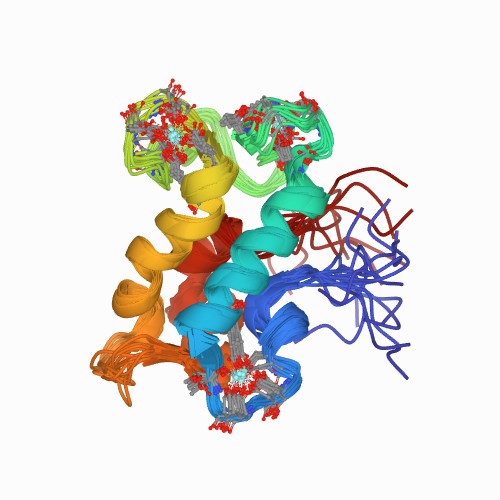

The new method takes advantage of a bacterial protein called Lanmodulin, that is almost a billion times better at binding to rare earth elements than to other metals. It can provide a more environmentally friendly way to extract and separate rare earth metals from other metals and from each other.

The protein is able to be used for many cycles, it offers an attractive eco-friendly alternative to the methods currently used.

The research team separated Yttrium from Neodymium both with greater than 99% purity. They also separated Neodymium from Dysprosium with greater than 99.9% purity.

Researchers plan to optimize the method to obtain the highest-purity products and so it can be scaled up for industrial use.

English

English Arabic

Arabic