Green adhesives made from whey

For each kilogram of cheese, for example, 9 kilograms of whey are produced. Some of this is processed further, for example into whey-based drinks with fruit additives or other mixed drinks. The lactose and proteins contained in the whey can also be separated and used in other ways, for example, as a raw material in pharmaceuticals or in baby food.

However, once the proteins and lactose have been separated, molasses remains. Disposing of this substance is very complicated and expensive, due to its relatively high salt content.

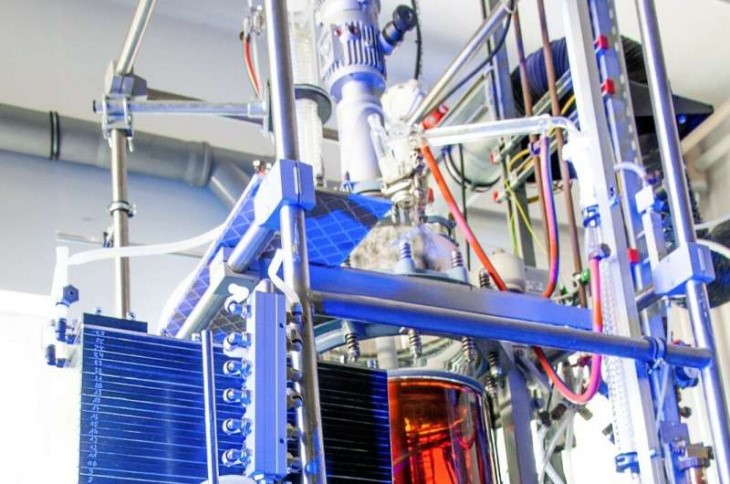

Researchers have now developed a process for extracting valuable ethyl acetate by using special membrane, from the molasses. Ethyl acetate is often used when manufacturing adhesives, printing inks or varnishes. It can also be used to clean surfaces.

Until now, ethyl acetate has been produced from natural gas and petroleum derivatives. Producing ethyl acetate from whey, on the other hand, results in a product that is clearly superior when compared to environmentally harmful solvents because of its easy microbial degradability and it is also independent of the price fluctuations of natural gas and crude oil.

Another advantage: the process developed renders the need for costly disposal of molasses unnecessary. The separated ethyl acetate offers a high purity of 97.5% and can thus be used immediately as a raw material without further processing steps.

English

English Arabic

Arabic