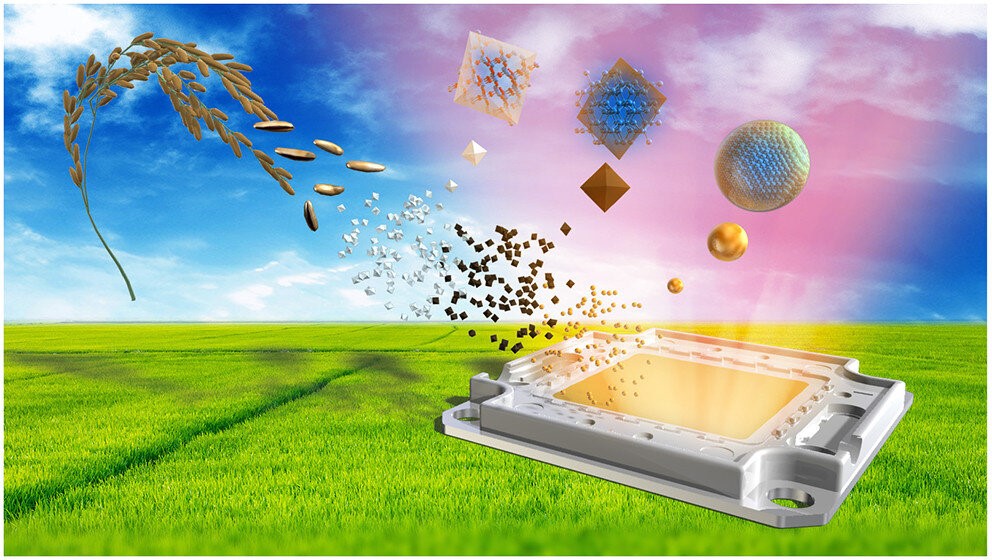

First LED lights developed from rice husks

Milling rice to separate the grain from the husks produces about 100 million tons of rice husk waste globally each year.

Waste rice husks, it turns out, are an excellent source of high-purity silica (SiO2) and value-added Si powder. Si has photoluminescence properties, stemming from its microscopic (quantum-sized) dot structures that serve as semiconductors.

Scientists used a combination of milling, heat treatments, and chemical etching to process the rice husk silica. Then Silica powder was chemically functionalized for high chemical stability and high dispersity in solvent, with 3 nm crystalline particles to produce the (quantum-sized) dot that luminesce in the orange-red range with high luminescence efficiency of over 20%.

The LEDs were assembled as a series of material layers. An Indium-Tin-oxide glass substrate was the LED anode; it is a good conductor of electricity while sufficiently transparent for light emission. The material was capped with an Aluminium film cathode.

Their new method transforms agricultural waste into state-of-the-art light-emitting diodes in a low-cost, environmentally friendly way.

انكليزي

انكليزي عربي

عربي