Extract rare-earth elements from waste

A new rapid heating technique can extract rare-earth elements from both industrial and electronic waste. The technique provides a far more sustainable alternative to existing extraction methods with concentrated acidic chemicals.

This method is not only both resource- and pollution-intensive, but also are far harder to dissolve and can extract dangerous amounts of radioactive elements.

In addition, REEs are contained in the immense quantities of old consumer electronics we throw out each year, most of which just sit in landfills for decades as they decay.

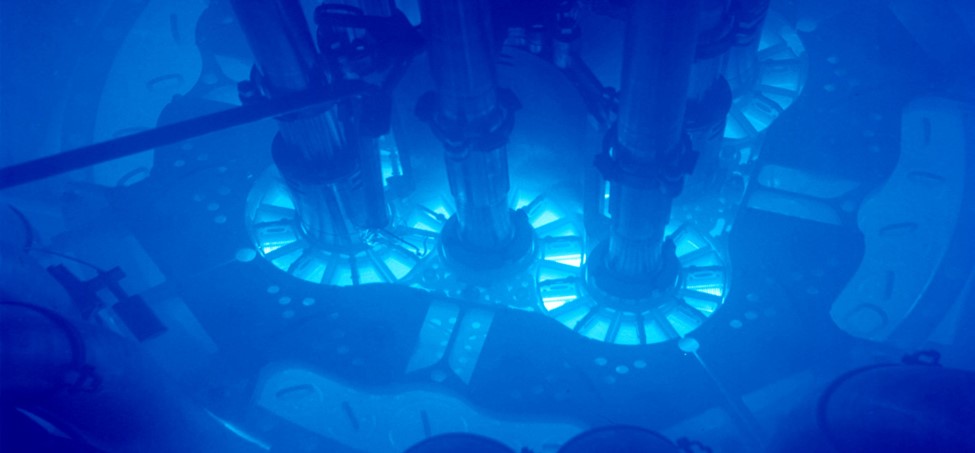

Researchers now suggest that these REEs could be extracted easily and sustainably through a technique named ‘flash Joule heating’ (FJH).

FJH is an ultrafast electrothermal process where materials are first slightly compressed inside a quartz tube and then loaded between two graphite electrodes — themselves connected to a bank of charged capacitors. As the capacitors discharge, a high voltage is rapidly generated between the electrodes, heating materials in the tube to some 3,000°C in one second.

Researchers loaded the quartz tube with a mixture of coal fly ash and electrically conductive Carbon black, which was produced by the burning of petroleum products like gasoline and diesel.

When rapidly heated in this way, the researchers found that REE phosphates and glasses in the ash quickly decomposed to form highly soluble REE oxides, which could then be flushed out by a solvent.

In the most common types of fly ash, the REE yields extracted by the process were more than 200% higher than what would be possible through leaching the waste with concentrated acids.

By using these sustainably-sourced REEs in next-generation technologies, the ability of our society to coexist with nature could drastically improve.

English

English Arabic

Arabic