A simple technique to evaluate the recycled content of new plastic products

Researchers have developed a simple, fraud-resistant technique to evaluate the recycled content of new plastic products. They added a fluorescent tag to plastic resins, successfully tracking their amount in products made with various polymers and colors.

They tagged recycled polymers with the fluorescent molecule 4,4, -bis(2-benzoxazolyl) stilbene (BBS), and then track the tagged plastic feedstocks into resulting products. BBS’s fluorescence intensity and color vary when different levels are present. It’s also inexpensive and approved for food contact applications.

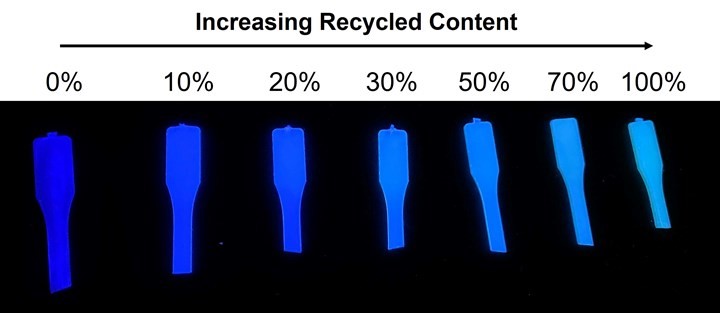

The researchers mixed small amounts of BBS into melted high-density polyethylene (HDPE) and then mixed that with virgin HDPE resin, simulating 0 to 100% recycled-content materials. As the amount of BBS-tagged HDPE rose in the samples, the fluorescence intensity shifted toward a greener hue of blue under a fluorescent light.

They developed a simple digital image analysis technique to convert the material’s fluorescence into the percentage of recycled content.

The method could identify the recycled content in other real-world polymers, including recycled milk bottles with additives, colored HDPE, polypropylene and poly (ethylene terephthalate).

Researchers say the BBS strategy could be applied to a variety of single-use plastic products without impacting their appearance or quality.

English

English Arabic

Arabic