Making seawater drinkable in minutes

Despite the vast amount of water on Earth, most of it is seawater and freshwater accounts for only about 2.5% of the total. One of the ways to provide clean drinking water is to desalinate seawater.

A research team has developed co-axial electro-spun nanofiber membranes fabricated by an alternative nano-technology, which is electrospinning. This new desalination technology shows it has the potential to help solve the world's freshwater shortage. The developed technology can prevent wetting issues and also improve the long-term stability in membrane distillation process.

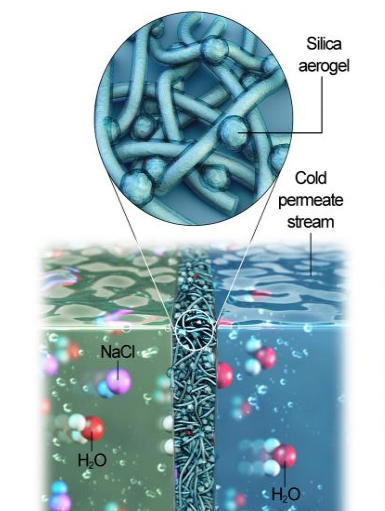

The co-axial electrospinning technique is one of the most favourable and simple options to fabricate membranes with three-dimensional hierarchical structures. The team used poly (vinylidene fluoride-co-hexafluoropropylene) as the core and silica aerogel mixed with a low concentration of the polymer as the sheath to produce a co-axial composite membrane and obtain a superhydrophobic membrane surface.

Most of the studies using electro-spun nanofiber membranes in membrane distillation applications operated for less than 50 hours although they exhibited a high water vapor flux performance. On the contrary, the team applied the membrane distillation process using the fabricated co-axial electro-spun nanofiber membrane performed a 99.99% salt rejection for 1 month.

The membrane is suitable for long-term membrane distillation applications as it possesses several important characteristics such as, low sliding angle, low thermal conductivity, avoiding temperature polarization, and reduced wetting and fouling problems whilst maintaining super-saturated high water vapor flux performance.

English

English Arabic

Arabic