Inventing glass so hard, it can even scratch diamond

Chemists has discovered the critical proportion of crystallized and amorphous Carbon needed to create a glass with remarkable properties that won't weaken under intense pressure.

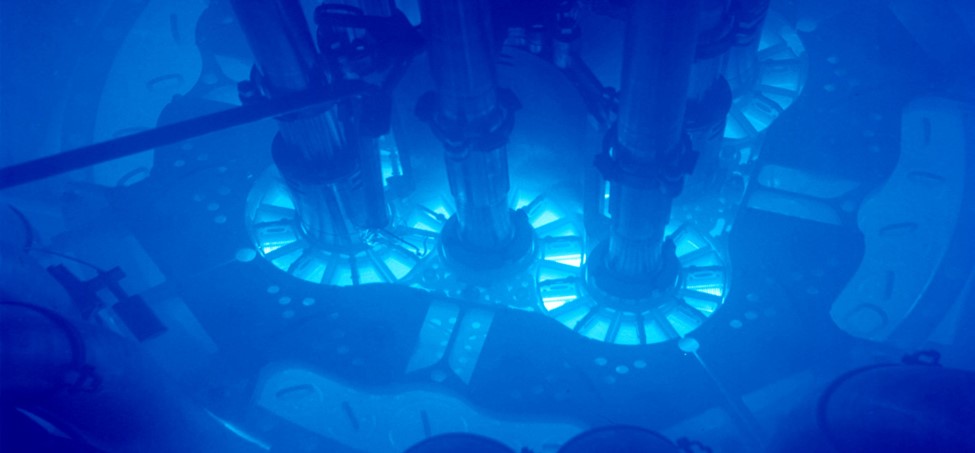

The team experimented, squishing spheres of Carbon atoms called 'buckyballs' under intense pressure of around 25 gigapascals (about 250,000 atmospheres) and then baking the mush at temperatures between 1,000 -1,200ºC.

Subjecting the products, dubbed AM-I, II, and III, to a litany of tests, the chemists mapped the way the atoms bonded with one another, showing they, all operated as a semiconductor on a level comparable with amorphous Silicon.

But it was the mechanical properties of the third result that truly stood out.

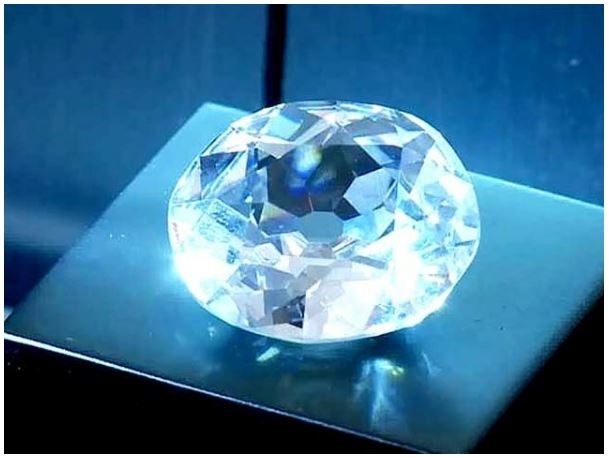

Diamond is characteristically known as one of the hardest known substances. A common measure of hardness, called the Vickers hardness test, actually uses a diamond tip to indent material. The harder the material, the greater the force (measured in gigapascals) required to leave a sizable mark.

Scratching another diamond might require somewhere between 60 and 100 gigapascals, depending on whether it's natural or made with care in a lab.

The glassy material AM-III measured somewhere between 110 and 116 gigapascals on the Vickers hardness test, making it the hardest amorphous solid to date. Running a slither of the substance along the flat face of a natural diamond left a clear score line.

English

English Arabic

Arabic