A super-thin slice of wood can be used to turn saltwater drinkable

Filtering the salt from seawater can take a lot of energy or specialized engineering. In membrane distillation, salty water is pumped through a film, usually made of some sort of polymer with very narrow pores that filter out the salt and allow only water molecules through.

This traditional water filtration, needs very high-pressure pumping to squeeze the water through, so it uses a lot of energy.

Jason and his colleagues developed a new kind of membrane made of natural wood instead of plastic.

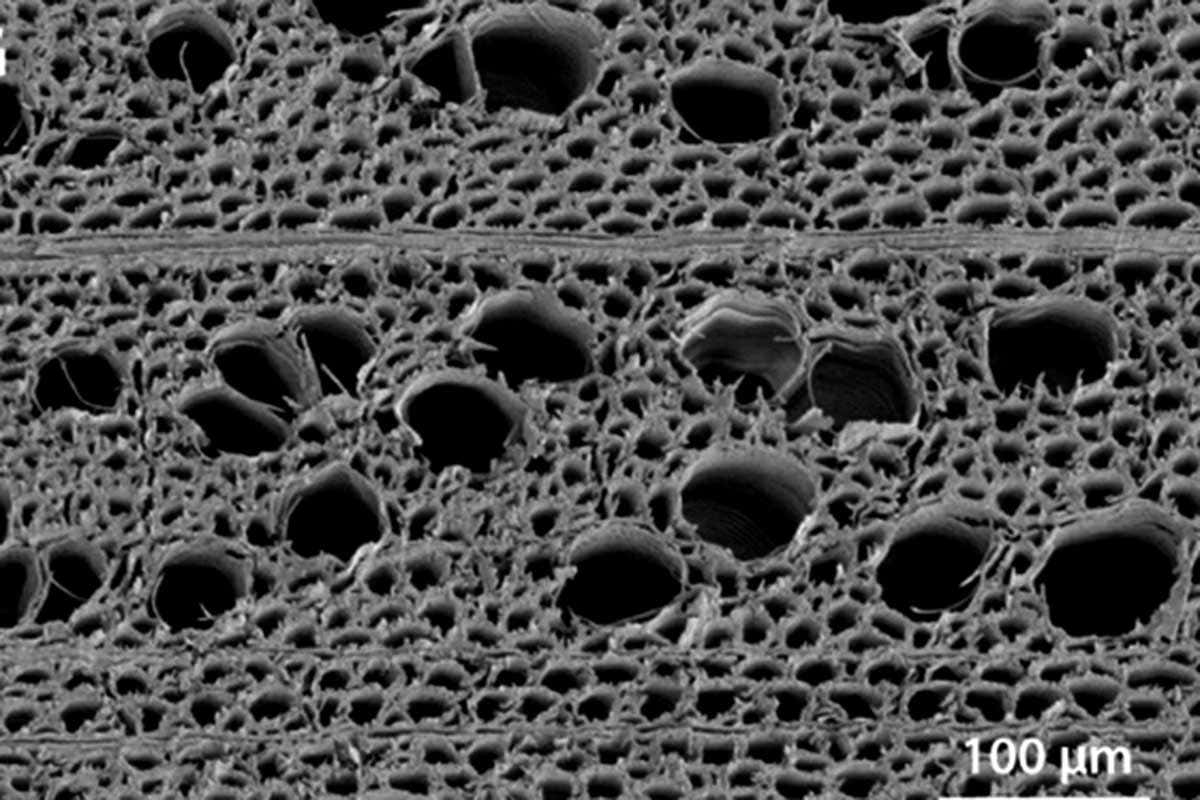

The new team’s membrane is made of a thin piece of American basswood, which undergoes a chemical treatment to strip away extra fibers in the wood and to make its surface slippery to water molecules. One side of the membrane is heated so that when water flows over that side it is vaporized.

The water vapor then travels through the pores in the membrane toward its colder side and leaves the salt behind, condensing as fresh, cool water. This takes far less energy than simply boiling all of the saltwater because there’s no need to maintain a high temperature for more than a thin layer of water at a time.

This method filters about 20 kilograms of water per square meter of membrane per hour, which is not quite as quick as polymer membranes. The researchers think that may be because they did not have the equipment to make their membrane as thin: it is 500 micrometers thick, whereas the polymer membranes are generally closer to 130 micrometers thick.

Making the wood membranes thinner shouldn’t be too hard with the right equipment, the rest is just a supporting structure to make it harder to break.

English

English Arabic

Arabic